Preventive maintenance is no longer optional—it’s the backbone of modern operations across construction, municipalities, mining, transportation fleets, hospitality facilities, and healthcare environments. But with dozens of platforms claiming to be the “best,” decision-makers face a familiar problem: how do you separate real capability from marketing noise? So, what is the best preventive maintenance software and what is the criteria to answer that question?

The truth is simple: The best preventive maintenance software is a modern CMMS (Computerized Maintenance Management System) that centralizes assets, work orders, workflows, compliance, and costs. This guide breaks down exactly what defines “the best,” what features matter most, and why organizations are turning to Four Winds CMMS to reduce downtime, extend asset life, and control budgets with precision.

Table of Contents

What Is Preventive Maintenance Software?

Preventive maintenance software is a digital system that automates and manages scheduled maintenance tasks so that equipment, facilities, and fleets run reliably—before failures occur.

But the best systems do far more than send reminders.

A CMMS integrates:

- Asset histories

- Parts & inventory

- Technicians & workflows

- Inspections & compliance

- Reporting & budgeting

- Predictive analytics

And this is why the term “preventive maintenance software” is often interchangeable with CMMS—but not all tools are created equal.

Key Points:

- The best systems produce measurable reductions in downtime and costs.

- True preventive maintenance requires automation + data, not spreadsheets.

- A CMMS centralizes asset and work order management across teams.

What Makes a Preventive Maintenance System “The Best”?

Stop looking at surface-level features.

The best preventive maintenance software has three universal traits:

1. It removes complexity.

Software should reduce workload—not add to it.

2. It centralizes everything

Assets, people, schedules, parts, costs, vendors—one location, one source of truth.

3. It delivers clarity for decision-makers.

Executives, engineers, and operations leaders should instantly see:

- Upcoming PM schedules

- Work order bottlenecks

- Cost centers

- Asset reliability

- Budget forecasts

Key Points:

- Ease of implementation and adoption determines success.

- Centralization creates efficiency and eliminates data silos.

- Reporting and decision-support tools are non-negotiable.

CMMS vs. Basic Preventive Maintenance Tools: Why It Matters

Many organizations still use:

- Excel

- Calendar reminders

- Whiteboards

- PM-only apps with limited functionality

These tools fail because they cannot scale.

A modern CMMS provides:

| Feature | PM Apps | CMMS |

|---|---|---|

| Work order management | Limited | Full lifecycle |

| Asset histories | Minimal | Comprehensive |

| Technician mobile app | Sometimes | Always |

| Inventory & parts | Rare | Integrated |

| Cost tracking | Uncommon | Detailed |

| Reporting | Basic | Advanced |

| Predictive insights | No | Yes |

Key Points:

- PM-only tools cannot support real-world operations.

- A CMMS delivers automation, visibility, and accountability.

- Organizations that upgrade typically see immediate ROI.

The Time & Cost ROI of a Modern CMMS

Let’s talk benefits decision-makers actually care about.

Preventive Maintenance ROI Benchmarks

Organizations typically achieve:

- 20–40% reduction in unplanned downtime

- 15–30% reduction in maintenance labor hours

- 10–25% increase in asset lifespan

- 15–20% reduction in parts and inventory cost

- 40–60% increase in team productivity

How?

Because a CMMS eliminates chaos and creates predictability.

Key Points:

- Even small organizations benefit from structured workflows.

- Operational efficiency dramatically increases with PM automation.

- Visibility reduces waste, emergencies, and overtime.

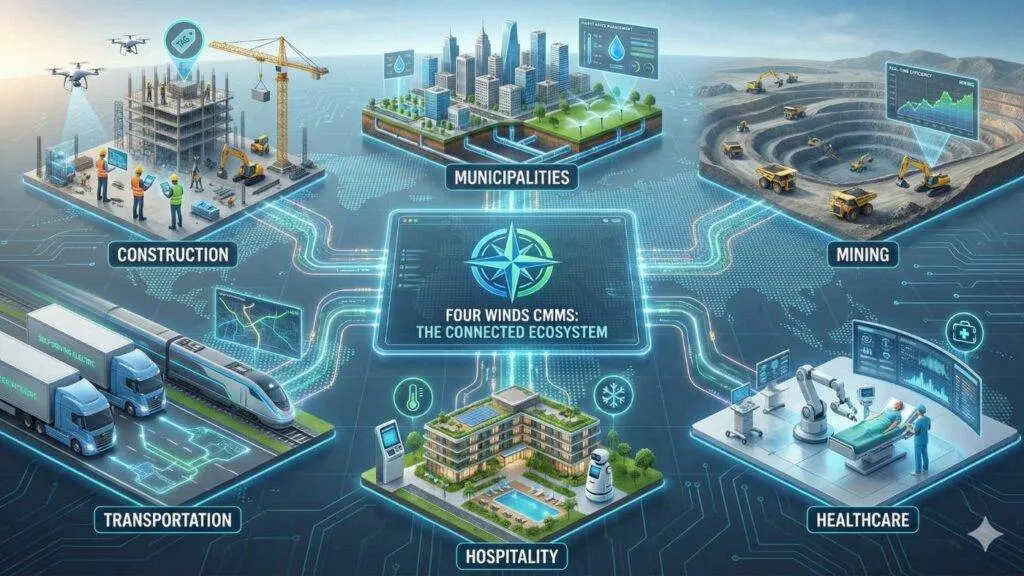

Why Four Winds CMMS Stands Out Across Industries

Four Winds CMMS isn’t just a tool—it’s a scalable platform designed for organizations that demand clarity, control, and cost-saving predictability. When people ask, “What is the best preventive maintenance software?”, we aim to have the answer be Four Winds CMMS>

What truly sets Four Winds apart is the leadership behind it. The founders bring decades of real-world maintenance, engineering, and enterprise software experience, having lived through every generation of maintenance technology—from on-premise systems to complex, heavily customized legacy deployments. Their firsthand understanding of what works (and what fails) in the field is the backbone of the Four Winds ecosystem.

Because of this deep expertise, Four Winds CMMS was engineered to bridge the gap between proven, time-tested maintenance principles and the speed, flexibility, and intelligence of modern SaaS. Organizations transitioning from outdated installed systems instantly recognize that Four Winds solves the frustrations they’ve dealt with for years—without sacrificing the stability they’ve relied on.

This unique blend of industry wisdom + SaaS innovation gives decision-makers a platform that’s practical, intuitive, and built for the long haul.

Industries that rely on Four Winds CMMS:

- Construction: Track fleets, equipment, and field service.

- Municipalities: Manage water, facilities, fleets, parks, utilities.

- Mining: Heavy machinery PM, inspections, safety workflows.

- Transportation: Fleet maintenance, DOT compliance, breakdown reduction.

- Hospitality: Facilities, HVAC, guest-facing assets.

- Healthcare: High-stakes, regulated equipment environments.

Core Four Winds Advantages

- Intuitive, modern interface

- Extremely easy onboarding for field technicians

- Real-time visibility for leadership

- Powerhouse PM scheduling

- Mobile-friendly field tools

- Asset lifecycle & cost management

- Excellent support for small through enterprise-scale teams

- It is innovative and flexible

Key Points:

- Four Winds is built for both modest organizations and large operations.

- Industry versatility makes it an all-in-one maintenance solution.

- Decision-makers gain transparency and control instantly.

Features Decision-Makers Should Demand in 2026

The maintenance landscape is evolving faster than ever. Organizations are adopting IoT sensors, AI-driven prediction, energy-efficiency mandates, and cross-department coordination. The “good enough for now” solutions of the past won’t support what’s coming next.

Your preventive maintenance software must not only solve today’s challenges—it must prepare your operation for a more automated, data-driven, compliance-heavy future. This section lays out the features that will determine who moves ahead and who gets left behind.

Key Points:

- Your CMMS must support modern predictive and mobile workflows.

- Scalability ensures your system won’t become obsolete.

- Flexibility and configurability protect your long-term investment.

- OSHA compliant for safety

Implementation Considerations for Organizations of Every Size

Choosing the right preventive maintenance system is only half the battle—successful implementation is where organizations win or lose. Even the best software falls flat without structured onboarding, clean data, and a strategy for technician adoption.

Whether you manage 50 assets or 50,000, the right approach makes the difference between a system people rely on and a system people avoid. This section walks through the elements that ensure your CMMS becomes a long-term operational advantage.

Key Points:

- Implementation determines real-world outcomes.

- Adoption by field teams is essential for accurate data and reliable PMs.

- Four Winds is designed for fast, smooth deployment.

Common Mistakes When Choosing Preventive Maintenance Software

Most organizations don’t fail because they chose the wrong maintenance software—they fail because they didn’t know what to look for. The market is saturated with tools that look polished but crumble under real operational pressure.

From underestimating the importance of training to overlooking reporting capabilities, many common mistakes lead teams into costly re-platforming or frustrated technicians who revert to old habits. This section reveals the pitfalls to avoid so your investment pays off.

Key Points:

- Cost-focused decisions often lead to long-term inefficiencies.

- Leaving technicians out of the evaluation process limits adoption.

- Strong reporting ensures leadership can justify budgets and decisions.

Next Steps: Build a Preventive Maintenance Program That Runs Itself

So did we answer, “What Is the Best Preventive Maintenance Software?”

Preventive maintenance success isn’t achieved with guesswork, spreadsheets, or outdated systems—it’s built on visibility, automation, and a platform engineered to support your organization’s real-world demands. Whether you oversee a small fleet or thousands of municipal, industrial, or facility assets, the next leap in efficiency comes from choosing a CMMS that delivers clarity, control, and proven ROI.

If you’re ready to:

- Eliminate unplanned downtime

- Extend asset lifespan and improve reliability

- Streamline technician workflows

- Strengthen compliance and reporting

- Bring order, predictability, and accountability to your entire operation

Then now is the ideal moment to take the next step.

Book a tour of our system with a Four Winds CMMS expert and see how a modern, scalable CMMS can transform your preventive maintenance program from reactive to reliably proactive.

This no-obligation conversation will help you evaluate your workflows, identify opportunities for improvement, and determine whether Four Winds CMMS is the right fit for your operational goals.

Schedule your personalized tour and start building the maintenance system your team deserves.

FAQs

Q: How does preventive maintenance software differ from a CMMS?

A: Preventive maintenance tools focus on scheduling; a CMMS manages scheduling plus assets, inventory, costs, reporting, and workflows.

Q: Is preventive maintenance software valuable for small organizations?

A: Yes, even modest operations see major benefits from structured PM management

Q: How fast can teams implement Four Winds CMMS?

A: Most organizations become fully operational within days to weeks.

What are the primary benefits of using a CMMS in terms of time and money?

A CMMS delivers measurable savings by reducing unplanned downtime, automating preventive maintenance schedules, and streamlining technician workflows. Organizations typically see 20–40% less downtime, 15–30% fewer labor hours spent on reactive repairs, and a 10–25% increase in asset lifespan, all of which directly improve operational budgets.

On the time side, a CMMS eliminates manual tracking, reduces administrative burden, speeds up work order completion, and ensures technicians always know what to do, when to do it, and what parts are required. On the money side, it cuts emergency repair costs, prevents premature asset failure, improves inventory control, and gives leadership the data needed to forecast budgets with confidence.